Our Blog Posts

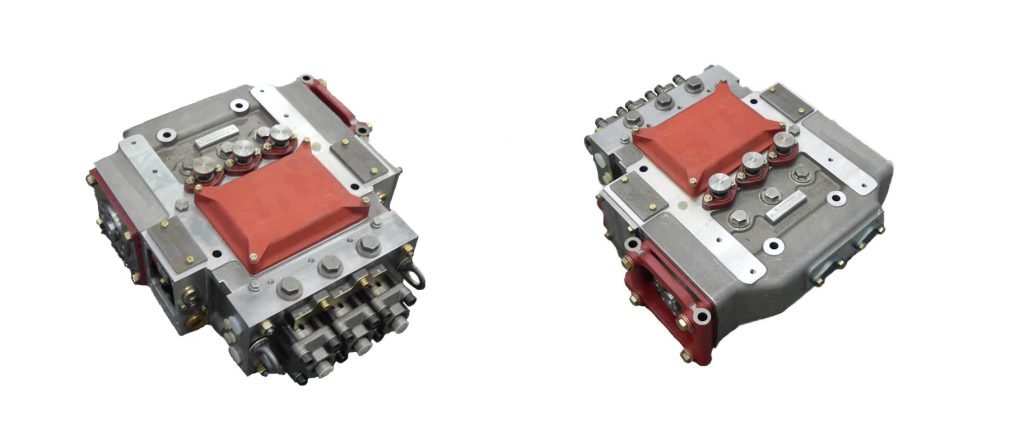

MWM-DEUTZ 628 – Fuel Pump Repair

The diesel fuel pump is undeniably one of the most critical components of a diesel engine, ensuring the precise delivery of fuel to power the heart of various industries. However, like any mechanical part, the fuel pump is subject to wear and tear over time, leading to potential issues that can impact engine performance. In this post, we will take a detailed look at the diesel fuel pump repair process, highlighting the steps involved in restoring its efficiency and reliability.

Disassembling and Cleaning the Fuel Pump

The repair process typically commences with carefully detaching the fuel pump from the engine. Once accessible, the pump is meticulously disassembled, and each component is inspected for signs of damage or wear. Accumulated fuel residues, dirt, and oxidation remnants are then thoroughly cleaned from the components using specialized cleaning agents and processes. This step ensures that the fuel pump is free from contaminants that might hinder its proper function.

Identifying and Replacing Worn-out Parts

During the repair process, the skilled technicians identify parts that have suffered wear, damage, or have lost their functionality. Key components like injectors, pistons, and seals are evaluated to determine if they require replacement. Replacing these worn-out parts with approved and high-quality OEM components is crucial to restore the fuel pump’s efficiency and performance.

Expert Repairs for Salvageable Parts

In some cases, certain parts of the fuel pump can be repaired rather than outright replaced. Skilled technicians assess the feasibility of repairing these components and conduct the necessary repairs using specialized techniques and top-grade materials. By salvaging and restoring these parts, the overall repair cost can be minimized without compromising on performance.

Rigorous Testing and Quality Assurance

The final phase of the repair process involves comprehensive testing of the repaired fuel pump. State-of-the-art testing equipment is used to assess the pump’s performance, verifying that it operates flawlessly, delivering the right fuel pressure and flow rates. These tests are essential to guarantee the pump’s reliability and safe operation before it is returned to service.

The diesel fuel pump repair process is a meticulous and carefully executed series of steps aimed at restoring the pump’s performance and reliability. A well-repaired fuel pump ensures that diesel engines continue to function optimally, providing power and efficiency to various industries. By entrusting the repair process to skilled and experienced technicians and prioritizing regular maintenance, operators can ensure that their diesel fuel pumps remain in peak condition. With a properly functioning fuel pump, engines can run efficiently and reliably, contributing to a greener and more sustainable future in the maritime and transportation sectors.

https://www.youtube.com/watch?v=mOMX0Dxxu-I&pp=ygUOxZ9pbcWfZWsgcG9tcGE%3D