- Home

- Services

Our Services

With 30 years of experience in the industry, we work diligently to ensure that the important components of your ships operate in a healthy and efficient manner. As Şimşek Pump, we offer various maintenance and repair services to the ship industry. The areas we specialize in are broken gear repair, governor, injector, diesel fuel pump and turbocharger maintenance and repair services. Being close to Tuzla Shipyard allows us to provide fast and effective service. Customer satisfaction is always at the forefront and we are happy to support you with our understanding of quality service.

All Our Services

We want you to know that we are ready to support you whenever you need us.

Governor

Governor overhaul and repair services

Governor

Governor overhaul and repair services

Broken Gear

Broken Gear repair services.

Broken Gear

Broken Gear repair services.

Injector

Injector overhaul and repair services

Injector

Injector overhaul and repair services

M/E Main Machine Fuel Pump

M/E Main Machine Fuel Pump overhaul and repair services

M/E Main Machine Fuel Pump

M/E Main Machine Fuel Pump overhaul and repair services

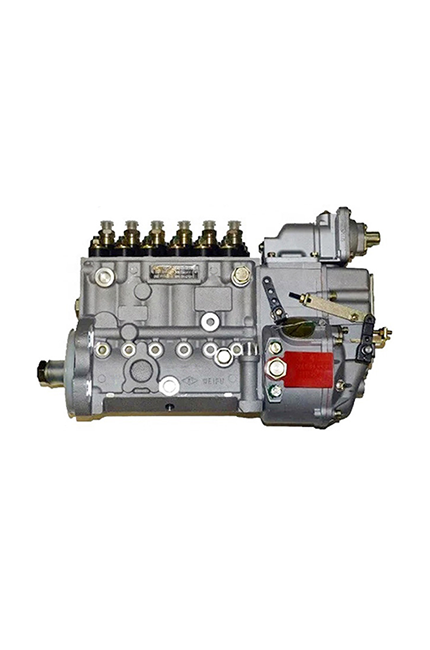

D/G Fuel Pump

Diesel Generator Fuel Pump overhaul and repair services

D/G Fuel Pump

Diesel Generator Fuel Pump overhaul and repair services

Piston

Piston overhaul and repair services

Piston

Piston overhaul and repair services

Turbocharger

Turbocharger overhaul and repair services.

Turbocharger

Turbocharger overhaul and repair services.

Camila

Managing Director

Camila

Managing Director

- Phone:+1 (859) 254-6589

- Email:info@example.com

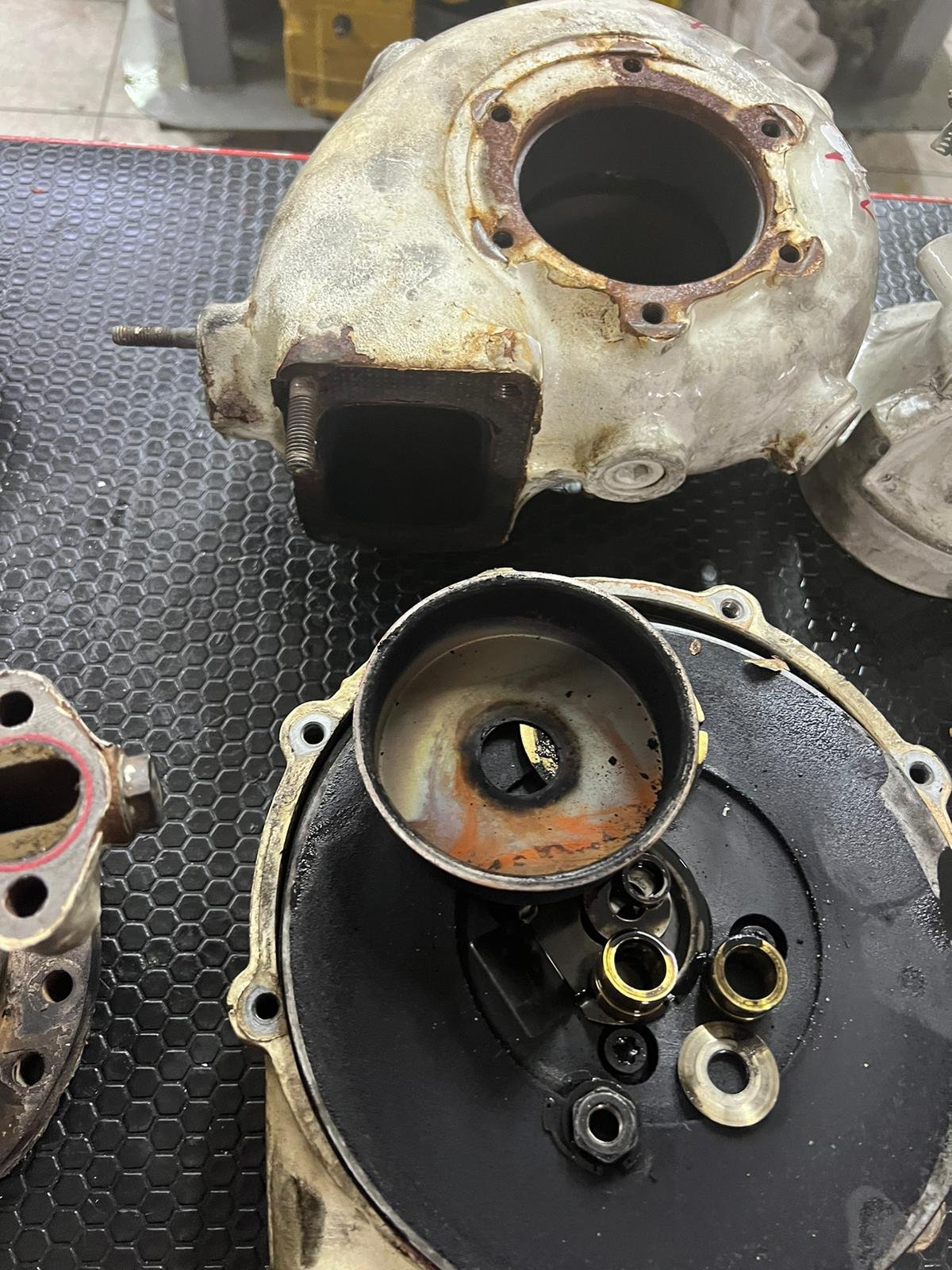

Turbocharger Overhaul and Repair Services

Ships’ turbocharger systems are important components that increase engine power and optimize fuel efficiency. As Şimşek Pompa, we perform turbocharger maintenance, cleaning, repair and revision with our expert team. We offer quality service to increase the performance and durability of your turbochargers. Our turbocharger maintenance and repair services include:

- Thorough Inspection: Our experienced technicians conduct a detailed inspection of the turbocharger to identify any signs of wear, damage, or performance issues. We utilize advanced diagnostic equipment to assess the condition of the turbocharger components.

- Cleaning and Maintenance: We employ professional cleaning techniques to remove any built-up deposits, carbon residue, or contaminants from the turbocharger. This ensures optimal airflow and prevents any potential damage to the internal components.

- Component Replacement: If any components are found to be worn out or damaged beyond repair during the inspection, we replace them with high-quality, genuine parts. We have access to a wide range of turbocharger components to ensure a precise fit and reliable performance.

- Balancing and Calibration: Balancing the rotating parts of the turbocharger is crucial for reducing vibrations and extending its lifespan. Our technicians perform precision balancing to ensure smooth operation and minimal stress on the turbocharger.

- Performance Testing: Before the turbocharger is installed back into your vessel, we conduct rigorous performance testing to ensure its efficiency, boost pressure, and overall functionality. This testing phase allows us to verify that the turbocharger is operating at its optimal levels.

- Warranty and Customer Support: We stand behind the quality of our work and offer warranty coverage on our turbocharger overhaul and repair services. Our dedicated customer support team is always available to address any questions or concerns you may have throughout the process

With our expertise in turbocharger overhaul and repair, we aim to improve the performance and reliability of your ship’s engine. By entrusting your turbocharger maintenance needs to Şimşek Pompa, you can be sure that your turbo will be in safe hands

Piston Overhaul and Repair Services

Piston systems on ships are critical components that keep the engine running efficiently. As ŞimşekPompa, we detect the wear or damage that may occur in the piston and carry out the necessary maintenance and repairs meticulously. We work with our expert teams to restore your pistons to their original performance and durability.

Our Piston Overhaul Process

When it comes to piston overhaul and repair, we follow a meticulous process to deliver top-quality results. Our experienced technicians conduct a thorough inspection of the pistons, identifying any signs of wear, damage, or performance issues. We utilize advanced diagnostic tools and techniques to assess the condition of the pistons and determine the most effective course of action.

Our Company

Evliya Çelebi, Giptaş, Pertev Sk. Sanayi Sitesi No:6, 34944 Tuzla/İstanbul

© 2023 – Created by design Entegresis Software All Rights Reserved.